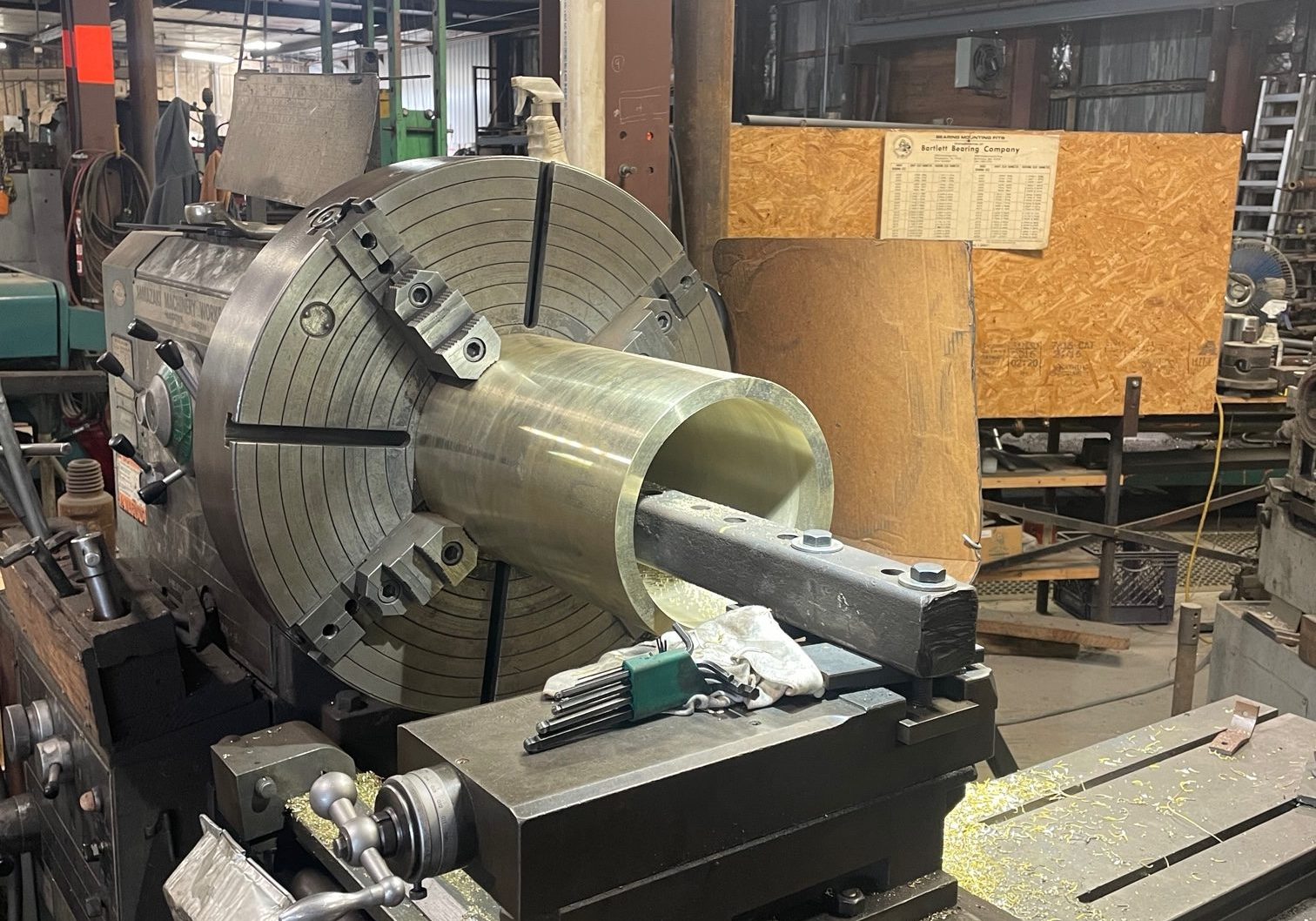

MACHINE SHOP

Our expert machinists and precision equipment allow you to repair instead of replace your equipment.

With our precision equipment and expert machinists, we offer you significant savings over replacement costs.

Our Machine Shop offers some of the finest machining capabilities in Pennsylvania. Machine work and salvage are the backbones of savings in hydraulic repairs.

Our assortment of equipment allows us to resurface, thread, cut, hone, straighten, and modify various mechanical components. We have decades of experience with motor-driven mechanical systems involving gearboxes and pumps. If you have a mechanical system that has seized, or with a bearing assembly leaking oil, contact Penn Equipment and we can diagnose your problem and get you back up and running.

We are staffed with certified and highly skilled machinists that operate a variety of precision equipment. We produce the highest quality, precision-machined heavy equipment parts.

- Shafts, bushings, couplers, sleeves, pins, rollers, pulleys, shims, discs, keys and keyways

- Studs, bolts, and nuts

- Wear rings and wear plates

- Valve components and hydraulic components

- Frozen bolts, drills, and taps

Parts can be salvaged at a fraction of the price of new parts.

For more information, contact Chuck Webber Jr. in our Welding & Fabrication Shop at cwebber@pennequip.com.

MACHINE SHOP CAPABILITIES

-

MAZZAK ENGINE LATHE

• Gap bed 34” diameter X 120”

between centers

• Gap removed diameter: 46”

• Max steady capacity 17 ¾” diameter

• Spindle thru hole: 4” diameter

• Metric and English threads -

DAVIS KEYSEATER

• Maximum key size 1 ¼”

• Minimum key size 1/8”

• Maximum diameter 32”

• Oster Pipe Ridged

• Threading/Bolt Machine

-

MILLING/BORING

• Universal Horizontal

Boring Machine

• Capabilities: boring, drilling,

milling, reaming, tapping and

in-house line boring

• Capacity: 79” 49” table, 100” spindle to tailstock

• Center to center of spindle

• Side to side: 60”

• Up/down: 46 ½”

• Spindle travel 26” -

DRILLING

• American Radial Arm Drill Press

• Max height over table: 70”

• Arm length: 6’

• Capabilities: drilling, boring, reaming, tapping

-

MILLING

• Kearney Trecker Mill

• Capabilities: milling, drilling, boring, horizontal, vertical, hob milling

• 3-axis digital readout

• Capacity: 96” x 20” table

• “x” = 53”

• “y” = 14”

• “x” = 21” -

TURNING

• Cincinnati Hypro 72 Vertical Turret Lathe

• Capabilities: turning, boring,facing, 2 vertical heads

• 1 horizontal head

• Capacity 6’ diameter X 6’ tall

• Lodge and Shipley Engine Lathe

• Maximum diameter 28 ¼’

• Between centers: 12’

• Spindle thru hold 2 ½” diameter

• English threads only